JCE Celebrates Innovation Award Win at Northern Star Business Awards

PRESS RELEASE JCE Energy Ltd., a specialist in off-grid power solutions for hazardous areas, has been awarded the prestigious Inspiration…

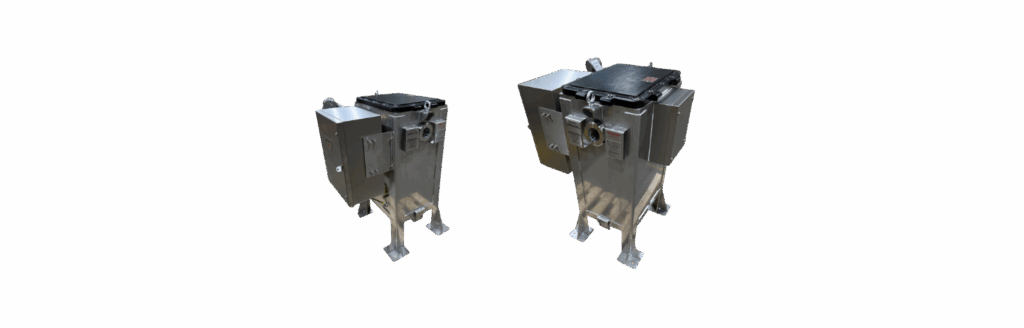

JCE have recently developed a custom oil filled resistor assembly, we were approached by our client who had an urgent requirement to house a high power resistor used for starting a DC motor application in a Zone 1 area. On top of the already tight timescale, the product had to be IECEx certified. Using JCE’s wealth of knowledge and experience we were able to design the product from the ground up, manufacture & complete the IECEx certification process all within the clients timescale.

The oil-filled resistor enclosure system is a complex assembly of components, each specifically designed with a type of explosion protection to ensure safety in hazardous environments, in accordance with IECEx/ATEX standards. The key components of this system include an Ex db temperature switch, an Ex ob resistor enclosure, an Ex eb terminal enclosure, and Ex eb glands. Each component employs different safety methods tailored to its operational requirements.

The Ex ob resistor enclosure relies on oil immersion for its protection. In this method, the electrical components inside the enclosure are submerged in oil, creating a barrier against the potentially explosive atmosphere outside. Any sparks, arcs, or hot surfaces generated by the resistor are contained within the oil, preventing them from igniting surrounding gases or vapors. This approach is particularly effective for equipment where sparks or heat may naturally occur during operation, providing a reliable method of explosion prevention by isolating ignition sources from the hazardous environment.